No farmer, merchant, businessman or resident should be without the

convenience of telephone service. Farmers can keep in touch with packers and

shippers, customers with businessmen and merchants. It is available for

emergencies, and enables the ladies of the community to keep abreast of the

latest social news. The construction of your very own telephone line is not such

a complicated job requiring scientific skills. The construction and installation

of a telephone system has been made simple here. Just follow eight easy,

do-it-yourself steps.

Step 1: The first step is the decision to build the line and determine who is

going to pay for it. How many circuits will be necessary, and will the

construction be of the bracket or crossarm type? The bracket method should never

be used where there is a possibility of more than two wires ever being placed on

the pole. The approximate cost of a full metallic circuit, crossarm type:

Step 2: Now that the potential telephone tycoon has become enthusiastic about

his new adventure, the next step of routing of the line is necessary. One must

be aware of locating, obtaining right-of-way, staking out, grading land,

trimming trees and underbrush, railroad, highway and power line crossings,

selecting poles, framing poles, crossarming, stepping, setting, etc. Sounds like

work, doesn't it? Is the potential line builder sure he still wishes to go

through with it? Employ some linemen to help. Starting pay for linemen is

generally $1.00 per day with no climbing, and $2.00 with climbing. Starting from

the initial point, measure off the distance at which the poles are to be set.

Following a straight line as much as possible, locate a stake in the ground. The

builder will find that following roads and railroad tracks is not only more

convenient and practical but the crew is not so apt to become lost in the woods

while trying to find the shortest distance.

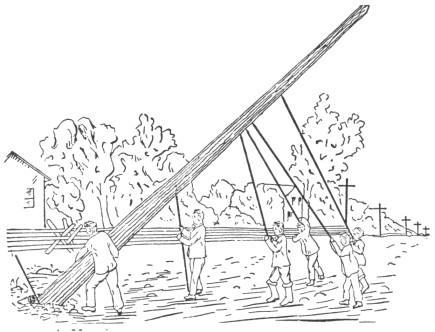

Step 3: Locate and select quality poles. Poles about 25 feet high should be

used on level stretches. The heaviest poles shall be placed on corners and

curves, and the best looking poles shall be placed in towns and in front of

residences. Poles allow the professional look to the job as well as being

practical; however, a tree and a beer bottle neck for an insulator has worked

fine for many lines However, if woods fires frequent the area, service can be

easily interrupted. It must be kept in mind that it usually takes eight or nine

men to plant a pole in the ground. Eight or ten poles are about as many as can

be set by the average gang in a day. All crossarms and braces shall, whenever

possible, be attached to poles before the poles are set. Poles shall be set in

concrete when sand is encountered, while all blasting of rock shall be in charge

of men experienced in the use of explosives.

Step 4: All pole hardware including glass insulators should be installed

next. Number 9 pony glass insulators should be used on rural lines. A locust or

oak pin, one inch in diameter fitted into a hole in the center of the crossarm

supports the glass insulator which is threaded to fit the pin

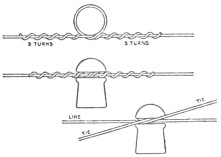

Step 5: Galvanized iron wire should be used in rural line construction Do not

do it the wrong way with fence wire stapled to trees. Static will be so bad, a

conversation will sound like a Fourth of July fireworks shoot. The line wire

should be carefully unwound along the line of the poles and drawn to the top of

each and tied to the insulators as shown in accompanying figure.

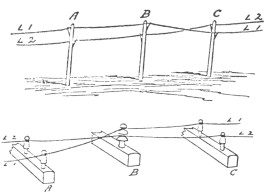

Step 6: To prevent interference from foreign currents and cross-talk between

circuits, the circuit must be transposed at about every quarter mile. The

accompanying figure indicates two satisfactory methods.

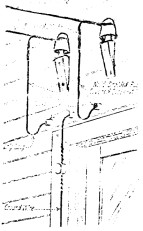

Step 7: Installing the instrument, The figure at the left indicates the

proper method for running drop wires. All instruments are to be grounded and

protected from lightning. Care should be taken when fastening the set to the

customer's wall. Before any holes are made, kindly confer with the lady of the

house for correct positioning. Do not allow customer to assist in the

installation of the telephone. Occasionally, patrons will want to try out your

new contraption for a few weeks, then have it removed before the bill is due.

Step 8: Rules of the line and servicing. Various suggestions should be given

to the patrons concerning service: Call by number only; treat operator

considerately; kind words improve service; answer all calls promptly; do not

call during a thunderstorm, as the company will not be liable for any injuries

received. In the event that there are several parties on one line, a distinct

ringing code must be given (1 long or 3 short rings, for example). All customers

on that line will know who is being called. (And, invariably, if they want to

know why, they will listen in.) When ringing, the caller will most likely hear

receivers coming up all along the line. Party line disputes will be common. A

charge of $2.00 per month is normal for telephone service.

Normal repair and maintenance on instruments and lines will be necessary.

Batteries in sets must be replaced periodically. Damage from storms and fires

may require a full time crew. Constant preventative maintenance will be required

of all equipment. Consult the rule book for bee or flea swarms or wild boar

encounters while in the field. However, run-ins with the natives (farmers with

shotguns) must be handled at the lineman's own discretion.